WEIDA’s manufacturing processes offer great flexibility to accommodate diverse specifications and industry needs. We provide customised plastic solutions tailored for a broad range of applications across multiple sectors. Our solutions include:

With years of experience in designing innovative rotationally moulded products, WEIDA ensures customer requirements are met with cost-effective, high-quality solutions. Leveraging the latest rotomoulding technology, tooling, and equipment, we deliver practical and innovative products across various applications.

Our customised services include:

Our team of highly qualified product designers and engineers utilises advanced design software, including SOLIDWORKS and AutoCAD to design both products and moulds, such as assembly components and integrated accessories, all developed in-house.

To ensure structural integrity, we perform Finite Element Analysis (FEA) on 3D models to simulate stress-strain behaviour under real-world conditions.

We employ experienced in-house toolmakers to fabricate sheet metal moulds for rotational moulding. For blow moulding, we use machined steel or aluminium moulds.

For more complex geometries or specific surface finishes, we offer cast aluminium or CNC-machined aluminium moulds, ensuring high precision, design flexibility, and superior finish quality.

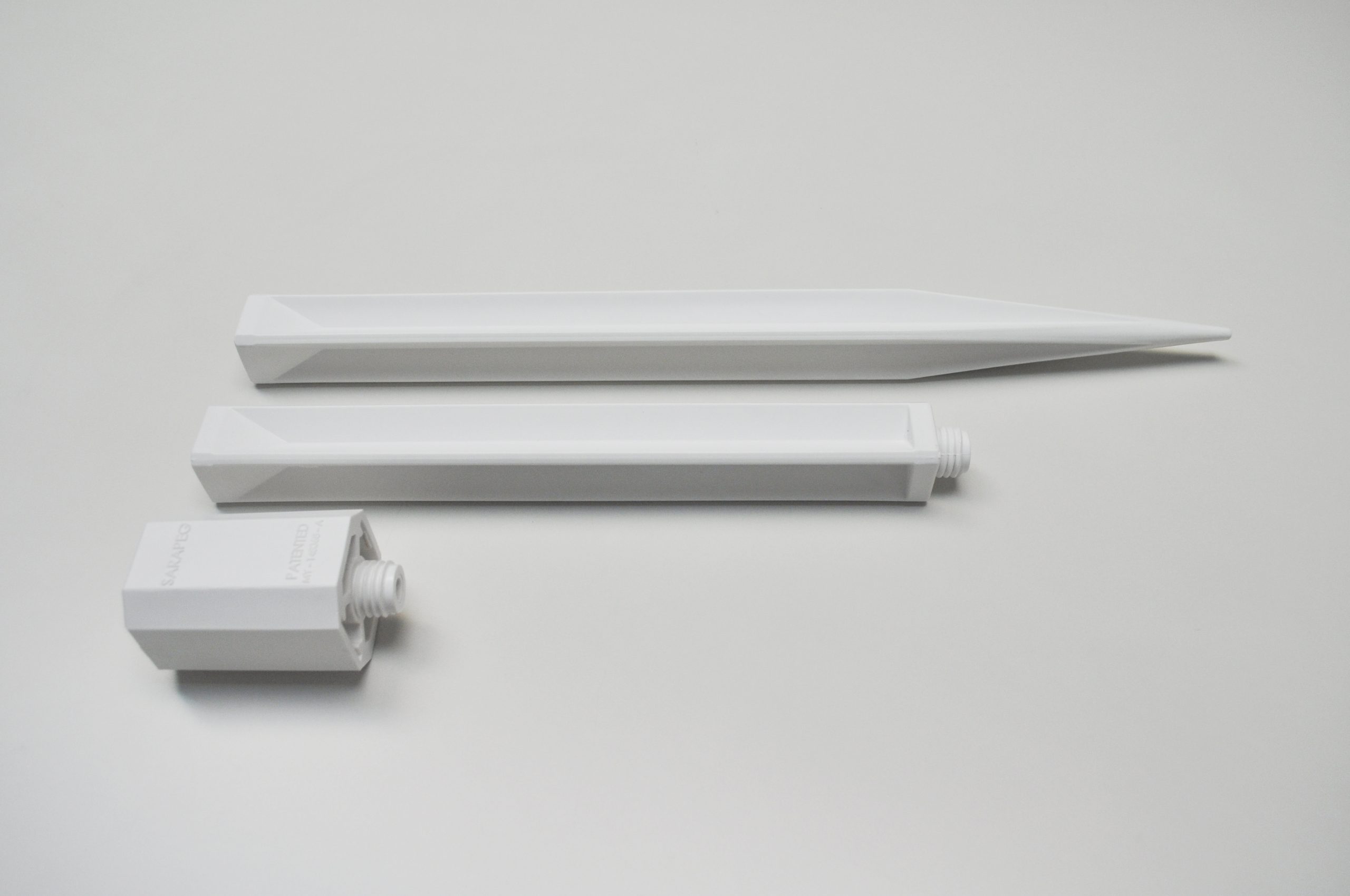

We provide a range of plastic moulding processes, selected based on product complexity, application, and production volume:

Our skilled assembly team specialises in thermal extrusion welding to fabricate structures using large HDPE pipes and sheets. This process enables the production of customised underground tanks, manholes, chambers, fittings, and other large-scale components designed to meet specific project requirements.